A little later we took our dingy in and explored the small town of

A little later we took our dingy in and explored the small town of

The next day we were off to knock down another hunk of the ICW. This hunk featured 10 draw bridges all with a different opening schedule. This really gets annoying and by the end of the day we have really had it with the ICW. Good news though…this brought us to  The wind has been blowing 15-20 knots from the due north for days now and has stirred up the ocean pretty good. We’d like that to simmer down a bit before we make our run. Ideally we are to be in

The wind has been blowing 15-20 knots from the due north for days now and has stirred up the ocean pretty good. We’d like that to simmer down a bit before we make our run. Ideally we are to be in

On Thursday we worked on the boat all day. My major accomplishment was to finally fix the y-valve in the aft head. It was frozen in the ‘flush overboard’ position (sorry Earth). I had a new one ready to install but I couldn’t get the hoses off the old one. For you sailors I think you know the hose I’m talking about…that white stuff that is very tacky and hard to work with. Add to this that I am stuffing myself under the sink in the head trying to muscle off these hoses. Now matter how hard I swore I couldn’t get a hose to budge even a millilmeter (like a 1/16 only smaller!). I decided that I was being too careful. This y-valve already didn’t work so why not just start cutting it to pieces with my Dremel. I had the Dremel plugged in and revved up when Sue said, “Would it do any good to take off those other three screws on the y-valve?” I thought not and said as much but didn’t want that to have been the clever solution after I was ripping away with my Dremel. Sure enough, by removing those screws I can take the guts out of the y-valve and guess what…they are the same guts as are in the new one! Way to go Sue! Now the hoses can stay in place and I can just do a one for one switch. I did and this now works as it is supposed to!

Weather reports are for the winds and seas to lay down for tomorrow and we plan an early start as we want to make sure we get to the marina in  WRONG! We walked north first of all. Just shabby neighborhood and run down businesses. We walked south…and then more south…and then more. All service businesses like upholstery, tires, walker tune ups, brain x-rays…that sort of thing. Being stubborn we ended up walking all the way down town…the entire 4+ miles. Finally there are a couple of restaurants, library, and book store but of course no groceries. We took a cab back!

WRONG! We walked north first of all. Just shabby neighborhood and run down businesses. We walked south…and then more south…and then more. All service businesses like upholstery, tires, walker tune ups, brain x-rays…that sort of thing. Being stubborn we ended up walking all the way down town…the entire 4+ miles. Finally there are a couple of restaurants, library, and book store but of course no groceries. We took a cab back!

Now maybe the weather will cooperate. Saturday looks to be the day they promised for Friday. The wind is supposed to be SE at 5 knots. We’d rather motor sail into this wind than negotiate the 23 bridges (I’m not kidding) between

Up anchor at dawn and off we go. Well, NOAA got it partly right. The wind is SE but more like 15 knots. That’s ok. We are under full sail, on course and making 6+ knots. Later in the morning the wind turned to be more south (of course). We were able to keep the main up and motor sail the  rest of the way. The ride got a little bumpy as we were barging into the seas but it was so great to back out on the ocean and out of the little ditch. As we made our way into the inlet for

rest of the way. The ride got a little bumpy as we were barging into the seas but it was so great to back out on the ocean and out of the little ditch. As we made our way into the inlet for

The cruise up the

The cruise up the

This is more of a boat yard than a

Christmas morning! Beautiful weather. We sit out in the cockpit having our morning coffee. There’s nobody here but us. Suddenly, Sue says, “What’s that floating down the river?” We both look and sure enough there is an entire hunk of pier, about 10 feet long floating down the river. But wait now it’s going up river…and now it makes a circle and what the…it’s got a bow wave! This thing is under power and that means something under the water is towing it. Yes, we see a line going under the water getting tight and then slack. On a close pass to our boat we see the brown shadow of a manatee. Poor girl has gotten herself tangled up in this thing somehow and can’t get loose.

Christmas morning! Beautiful weather. We sit out in the cockpit having our morning coffee. There’s nobody here but us. Suddenly, Sue says, “What’s that floating down the river?” We both look and sure enough there is an entire hunk of pier, about 10 feet long floating down the river. But wait now it’s going up river…and now it makes a circle and what the…it’s got a bow wave! This thing is under power and that means something under the water is towing it. Yes, we see a line going under the water getting tight and then slack. On a close pass to our boat we see the brown shadow of a manatee. Poor girl has gotten herself tangled up in this thing somehow and can’t get loose.

So we had to shoot her.

Just kidding!

Being a man of action I called the coast guard. They laughed until they stopped and then said a manatee rescue man would call me on the cell. Manatee Rescue Man called a few moments later and asked more details about where this thing was and said it would take him 30 -40 minutes to get there. (I suspect that much of this time was taken up by climbing into his Manatee Rescue Man Superhero costume.) Well that’s no good but I said ok and then Sue and I launched the dingy to go after the manatee ourselves. I had my knife in my teeth and a fearless gleam in my eye. Sue said I looked silly. As we rowed over toward the pier which was now bumping and crashing against pilings across the river another boat came out by us. It was the tow boat guys from yesterday. They had heard my call to the coast guard. Before either of us could get there a man across the river had figured out what was going on and managed to cut the manatee loose from the pier. So, just another standard Christmas morning!

One of my main projects is to finally have the time to install the 12 volt refrigeration on this boat. It came with engine driven cold plate refrigeration. I don’t care for this as it means you HAVE to run your engine probably twice a day to re-freeze the cold plates. But this boat has a 100 amp alternator and a wind driven generator. This is a better set up for 12 volt refrigeration then. Of course there are issues though….Where to put the compressor. It needs air flow to be able to do its job so you can’t stick it in a tiny locker. The instructions say that the engine room is ok but will need ductwork to bring outside air to the compressor. I have ductwork already in place and a nice shelf in the engine room where the old refrigerator business was so I decide that that’s where I’ll install the new compressor. The problem now is there are pipes and tubes running all over this boat and no diagram or labels. The previous owner said the system needed charging but that probably doesn’t mean there is no refrigerant in the system. Furthermore, as I trace down the copper tubing that carries the refrigerant I find that it seems to get tangled up with the copper tubing for the aft air conditioner!  Could those two things be sharing the same refrigerant supply? I wouldn’t install air conditioning on a boat but since it is here I want the option to use it. I’m imagining a time when we are living at a marina for awhile while working somewhere. When you live on the anchor you usually get a nice breeze and air conditioning is silly. When you are stuck back in a marina and no breeze it can be a welcome relief. That’s where you’ll have the 110 to run it anyway. So, after hours of climbing all over the boat I managed to make some diagrams of how things are hooked together to a point but was not willing to begin cutting tubing just yet.

Could those two things be sharing the same refrigerant supply? I wouldn’t install air conditioning on a boat but since it is here I want the option to use it. I’m imagining a time when we are living at a marina for awhile while working somewhere. When you live on the anchor you usually get a nice breeze and air conditioning is silly. When you are stuck back in a marina and no breeze it can be a welcome relief. That’s where you’ll have the 110 to run it anyway. So, after hours of climbing all over the boat I managed to make some diagrams of how things are hooked together to a point but was not willing to begin cutting tubing just yet.

Now it was nearly time for the Bears game! Maybe if we travel back down river toward town we can find a place that is open where we can get some food and watch the game. The dingy ride back down river was fun as I didn’t really get a good look at things on the way up being a little nervous following the boat ahead and being in new waters. I’ve never seen so many HUGE boats in one place.

DA BEARS!

Monday is an exciting day as we meet with our two main contractors for work we want done. First to come is John and Linda from our canvas company. We have a nice discussion about exactly what we want in our new dodger and they make the necessary measurements to get the job rolling. I can’t wait to get rid of this pontoon boat awning! While we were still talking with John and Linda Art showed up from Stem to Stern Boat maintenance. He is going to take care of engine and bottom work and maybe some other projects. He sees that we are still discussing canvas and says, “So, do you need to go to the store?” This guy is a former cruiser and as all cruisers know, a car is a valuable commodity. “YES, take Sue to the store and thank you.”

When they returned we had a nice long talk with Art from Stem to Stern Boat Maintenance. He is very knowledgable about boats (he built his own and went cruising for 5 years) and we put together a prioritized list of things that he and I need to do. He doesn’t care how much of any project I do myself. Some contractors won’t let the owner do any of a job as they want all the hours for themselves. Top of the list is why the engine is dripping oil and where is it coming from.  Next is removing the entire pulpit so it can be re-welded and put back. We are also going to replace all the lifelines at this time. Once the boat is hauled Art will have all the old bottom paint sanded off and we’ll go with a hard paint like Micron something or other. Other smaller jobs include fixing the knot meter, checking out the rudder bearing, replacing the through hull for the air conditioning (it’s frozen), checking on engine running temperature (I think 180 is a little high) and so forth. This is a great place to re-fit a boat. Every possible boat type of worker is in this town. We like Art and are glad he is on the job.

Next is removing the entire pulpit so it can be re-welded and put back. We are also going to replace all the lifelines at this time. Once the boat is hauled Art will have all the old bottom paint sanded off and we’ll go with a hard paint like Micron something or other. Other smaller jobs include fixing the knot meter, checking out the rudder bearing, replacing the through hull for the air conditioning (it’s frozen), checking on engine running temperature (I think 180 is a little high) and so forth. This is a great place to re-fit a boat. Every possible boat type of worker is in this town. We like Art and are glad he is on the job.

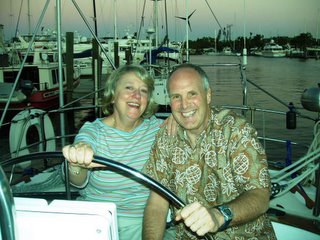

Finally we had our first visitors from back home! Rich P. and Mary Beth. Rich is a guidance counselor from Maine East and they were on vacation near

Finally we had our first visitors from back home! Rich P. and Mary Beth. Rich is a guidance counselor from Maine East and they were on vacation near

A busy day but things we have only been talking about over the last 1000 miles are now beginning to happen.

On Tuesday I started the official engine investigation. First job was to clean up the oil that was already there and wipe down the engine so we could detect exactly where the drip is coming from. This is not fun but I managed and then laid out fresh oil absorbing pads so we could look at them after about 24 hours. Now for removing the pulpit. Yikes, the pulpit meets the toe rail in four places each with four bolts that are through bolted. To get at the nuts we had to drag most of the chain out of the chain locker and remove the door to the chain locker in the v-berth. I could just about stuff upper half in there but I couldn’t turn or look up to find the bolts. SUE? Sue just fit! What a great crew.  I stuffed her in there with a socket and extension so she could hold the nuts while I turned the heads from top sides. Took us about and hour to get all 16 bolts out but we did it! The tricky part now is that the wires to the running lights are run through the tubing of the pulpit. I cut the wires up by the light where there is plenty of extra to repair later. I tied a line then to the end of the wire and began pulling it through the piping. No way. Way at the top the wire makes a nearly 90 degree bend. This is the two strand coated wire and very rubbery which makes it impossible to pull it around a tight bend like this. No solution was jumping up at us so we decided to leave that puzzle for Art tomorrow.

I stuffed her in there with a socket and extension so she could hold the nuts while I turned the heads from top sides. Took us about and hour to get all 16 bolts out but we did it! The tricky part now is that the wires to the running lights are run through the tubing of the pulpit. I cut the wires up by the light where there is plenty of extra to repair later. I tied a line then to the end of the wire and began pulling it through the piping. No way. Way at the top the wire makes a nearly 90 degree bend. This is the two strand coated wire and very rubbery which makes it impossible to pull it around a tight bend like this. No solution was jumping up at us so we decided to leave that puzzle for Art tomorrow.

We finished off the evening with wrapping presents for daughter and son-in-law who will be arriving tomorrow. Fun!