Hello to all. The long delay between posts is due to Scott getting a JOB! As long as we're in Fort Lauderdale for awhile I thought I might as well try to make back at least my yard fees ($28/day) by working. Yes, that's me in my official Stem to Stern team t-shirt. I've been taken on by the Stem to Stern guys who are doing the work on our boat! This works out great as not only do I get to make some cash I'm also learning a ton about boat mainenance by some true experts. (As you all know I only PRETEND to know what I'm doing after reading about it somewhere!) Art of Stem to Stern is trying to figure out how to bill me for me working on my own boat but I think I'm a little too sharp for that....maybe.

So far I've helped to pull wire on a 65 foot luxury yacht, sanded the decks of an old 45 foot fishing boat, polished the stainless (miles of it) on another luxury yacht, and helped to install the antenae on a 50 foot trawler. At first my body, although lithe and wirey, was complaining about doing physical labor but now all the parts seem to be working together more or less.

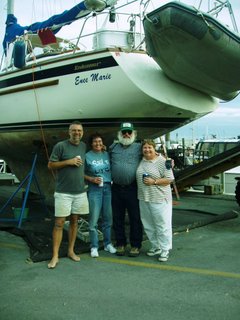

While I"ve been working in various boat yards on various boats, Sue has been slaving away on Enee Marie. She got the yard to set up some scafolding so she could sand down the wide toe rail and refinish with Cetol. It looks great and is now ready for us to re-install the bow pulpit which has been re-welded for us. Hopefully that will happen today along with beginning to string the new lifelines.

In a continuing effort to 'embrace the technology' I've hooked up with Vimeo so that I can embed video clips in this blog. Sorry, in the first one I didn't smile ...I was really concentrating. The second one is one of our attempts to digitally capture dolphins. Anyway, if interested, check out Vimeo. Really easy to get started!

View this clip on Vimeo

View this clip on Vimeo